World Zero Emissions Day (WZED) is celebrated annually on 21 September and was first introduced in 2008 as a day on which the planet took a ‘break’ from fossil fuel consumption.

In 2023, SKF has resolved to invest SEK 3 billion in its own operations to achieve the goal of decarbonisation by 2030, announcing a ban on the use of any fossil fuels and a plan to replace existing fossil fuels by 2029 with renewable or approved non-fossil energy sources.

Life Cycle Assessment (LCA) is an important method and tool for scientific emission reduction. 2023 May SKF released the world’s first rules for bearing product categories (PCR 2023: 03). 15 September, the Technical Specification for Life Cycle Evaluation of Bearing Products (T/CSTE 0410-2023) was officially released, with SKF China as the main drafting unit.

Rooted in China, contributing to the dual-carbon goal

Rooted in China and serving China, SKF is contributing to China’s “30, 60” dual-carbon goal by leveraging its rich cross-industry knowledge and practices, as well as its accumulated experience in exploring sustainable development.

The Technical Specification for Life Cycle Assessment of Bearing Products stipulates the basic rules and requirements for life cycle assessment of bearing products, including the determination of purpose and scope, life cycle inventory analysis, life cycle impact assessment, comparability, and elements supporting Type III environmental declaration, etc. It is a detailed requirement for carrying out life cycle assessment of products, and at the same time, as a rule for the product category, it is applicable to the related products for carrying out Type III environmental declarations (such as Environmental Product Declaration EPD) and Product Declaration EPD. Product Declaration EPD) and product carbon footprint assessment.

As the first domestic low carbon assessment standard for bearing products, the release of this standard will further standardise the life cycle assessment (LCA) of bearings and their components in China, and support the environmental impact assessment of related products from raw material extraction to end-of-life end-of-life.

A quick look at the highlights of the logo

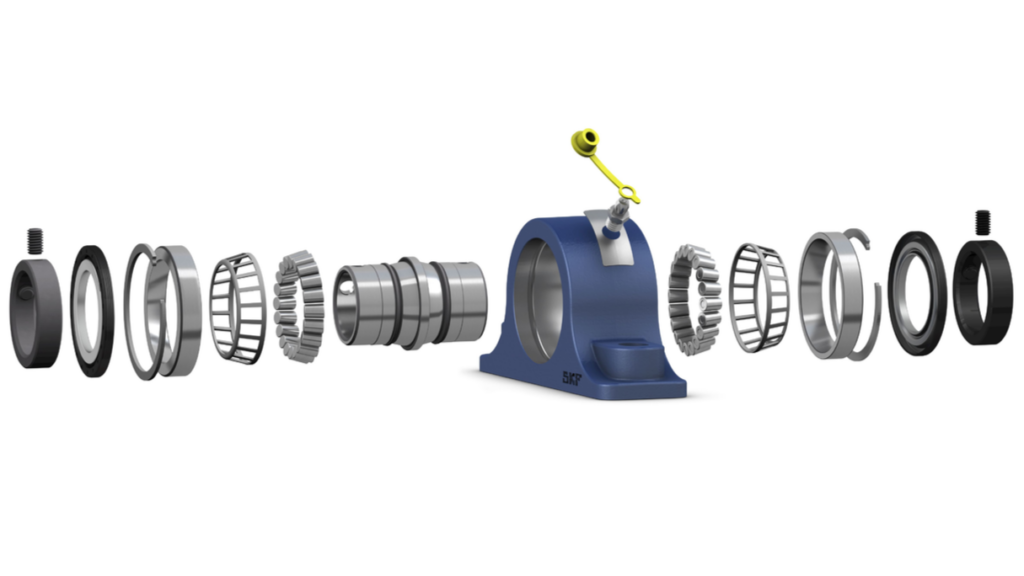

The product categories covered by this standard include rolling bearings, slide bearings, bearing assemblies and their components;

This standard extends the system boundary to “cradle-to-grave”, covering environmental impact analyses of bearing products in different scenarios at the downstream application end;

The standard defines clearer functional units according to the downstream application scenarios of bearing products;

Combined with the characteristics of bearing products, based on GB/T 6391-2010 and industry knowledge, the design service life calculation and reference service life of bearings are defined;

For the first time, the principle of calculating carbon emission in the rotation of bearing products in the use phase is defined, in which the work done to overcome friction loss in the use phase of bearing products should be calculated according to GB/Z 22559.2-2008;

The requirements for the use of on-site and off-site data are clearly defined, and reference is made to the use of the Data Quality Rating (DQR) standard provided in the European Product Environmental Footprint (PEF) guidelines;

Includes a model for calculating the environmental benefits at the end of a bearing’s life and specifies that the additional benefits of bearing remanufacturing should be included in the additional environmental information.

The Technical Specification for Life Cycle Evaluation of Bearing Products (T/CSTE 0410-2023) was drafted by SKF China, with the Swedish Academy of Environmental Sciences (SEAS), the China Standards Institution (CSI), Baoshan Iron and Steel Company Limited (BSIEC), Goldwind Science and Technology Company Limited (GSTC), and the Green and Low-Carbon Committee of the China Association of Standardisation (CASS) as the main drafting units, and proposed by China Society for Technology and Economics (CSTE) as the authoring unit.

SKF has been committed to the development strategy of “smart” and “clean”, continuous technological innovation, and promotion of synergistic cooperation. The release of the Technical Specification for Life Cycle Assessment of Bearing Products contributes to the power of the bearing industry for the national 1+N dual-carbon strategy, and helps the industry to further collaborate on carbon reduction and green win-win situation.