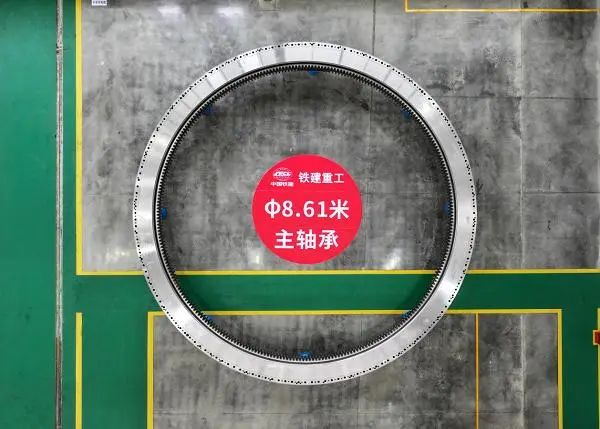

On 12 October, the main bearing of the shield machine with a diameter of 8.61 metres, which was independently developed by China Railway Construction Heavy Industry Group Corporation, came off the production line in Changsha’s Second Industrial Park.

This is so far the world’s largest diameter integral shield machine main bearing, breaking through the current shield machine main bearing development capacity of the “ceiling”, the domestic high-end underground tunneling equipment from now on a full range of independent intellectual property rights of the “Chinese heart”.

Difficulty in manufacturing is like carving a flower on a grain of rice

This set of main bearings by the China Railway Construction Heavy Industry Group independent research and development, can be used to drive the 18-metre large-diameter shield machine, the product weighs 62 tonnes, three-storey high, able to withstand over 10,000 tonnes of load; in the diameter of more than 8 metres in the plane of the raceway, the flatness of less than 20 microns, the difficulty of manufacturing is no less than carving a flower on a grain of rice.

It is understood that the shield machine main bearing is included in the 35 “neck” key technologies that constrain China’s industrial development, is the shield machine whole industrial chain of independent “last link”.

Shield machine is the “king” of intelligent complete sets of equipment for underground engineering, and the main bearing is the “heart” of the shield machine.

This “heart” is directly facing the shield machine super-heavy load, large partial load, frequent variable load and other extremely harsh working conditions, need to meet the key performance requirements of high reliability, long life. Its materials, design, manufacturing and testing is extremely difficult, at the top of the large high-end precision bearing industry chain.

If the shield machine main bearing industry’s independent innovation is compared to climbing the peak, then the attack on the world’s large diameter main bearing is like summiting Mount Everest.

In order to break through the weak link of the shield machine industry chain’s full autonomy, Tiejian Heavy Industry cooperates with upstream and downstream enterprises and colleges and universities to carry out collaborative research, and builds the world’s leading production line of shield machine main bearings, and has successfully developed a full series of main bearings ranging from 3 metres to 7.6 metres; and creates the world’s largest simulation test bench of the main bearings’ working conditions, which solves the world-wide problem that it is difficult to verify the testing of the main bearings of large-sized, low-speed and heavy-duty machines.

Achieved “full coverage” of main bearings for domestically produced shield machine.

According to China Railway Construction Heavy Industry Group chief scientist Liu Feixiang introduction, in the product development process, the development team from the design, materials, manufacturing, testing and other aspects of multi-directional force, comprehensive attack.

The development team developed a large diameter heavy-duty main bearing professional calculation software, developed a high-performance long-life bearing steel, breaking the main bearing fatigue life of traditional materials bottleneck.

After carrying out thousands of theoretical calibration and design optimisation, and analysing tens of thousands of inspection and test data, the team has made a breakthrough from the absence of multi-specification main bearings with diameters ranging from 3 to 7.6 metres, and finally realised the leap from the existence to the excellence of the independent design of the main bearing with a diameter of 8.61 metres.

In addition, the team has overcome the core key technologies such as deformation control of oversized thin-walled rings, processing of large modulus extremely hard teeth, heat treatment of complex profiles, etc., and fully verified the long-life service capability of the product to adapt to the complex and harsh working conditions.

The successful development of the main bearing of shield machine with a diameter of 8.61 metres marks that the development and industrialisation capability of domestic super-large-diameter main bearing has ranked among the world’s advanced level.

At present, TCCI has completed the complete independent development of main bearings from small diameter to super-large diameter, and has achieved the full coverage and localisation of the main bearing product spectrum from 3m diameter to 8.61m diameter.