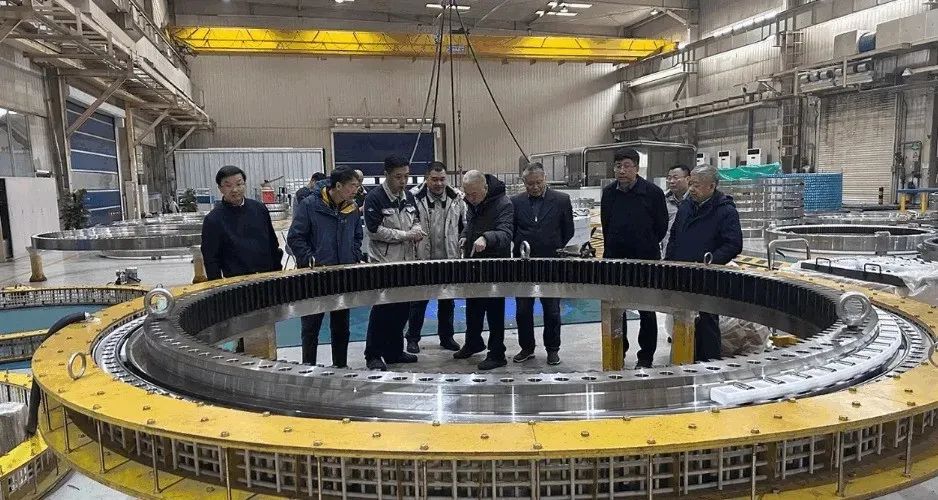

A few days ago, China Machinery Industry Federation in Wafangdian organised experts to appraise nine scientific and technological achievements of Waxaxial Group, such as the project of “low-temperature heavy-duty railway wagon bearing key technology research and application”.

The appraisal committee unanimously agreed that these nine projects are technologically advanced and have independent intellectual property rights, and agreed to pass the appraisal.

The appraisal committee, through the project report, review of relevant technical data, inspection of the site, and after questioning and discussion, considered that Waxaxial Group’s

“The key technology research and application of low-temperature heavy-duty railway wagon bearings,

The project of “R&D and Application of Suspension Bearing for Passenger Vehicle Shock Absorption System”, and the project of “High Temperature Resistant Tapered Bearing”,

The project of “R&D and application of high temperature resistant tapered roller bearings”,

The project of “Development and Application of Sectional Bearing Unit for Driveline of Marine Traffic Equipment”.

The overall technology has reached the international advanced level;

The project of “R&D and application of spherical roller bearings for extra-large high-pressure roller mill”,

The project of “Development and Application of Planetary Wheel Bearings for Wind Power Gearboxes”,

The project of “R&D and Application of Planetary Drive Bearing for Hub Drive of Large Mining Trucks”.

The overall technology has reached the domestic leading level;

The project of “R&D of double-row cylindrical roller bearings for independent spindles of high-speed and long-life machine tools”.

The project of “R&D and application of platform full complement cylindrical roller bearings for high load bearing and long life wind power drive”.

The overall technology has reached the domestic advanced level.

The project “Research on key technology and application of low-temperature heavy-duty railway wagon bearings” developed double row tapered roller bearings for low-temperature heavy-duty railway wagons, and designed compact unitised structure, overall light contact, low-temperature deformation of the sealing device, which improved the service life of the bearings, and according to the characteristics of the low-temperature working conditions, carried out the lubricating grease, Cage and sealing rubber materials for low-temperature selection test, to ensure the application performance of the bearing parts in the low-temperature environment;

In the project of “R&D and application of suspension bearings for passenger car vibration damping system”, the suspension bearings are designed to be composed of metal thrust bearings and outer plastic shells, and the outer shell and base are connected by the structure of “inverted snap”, which ensures the assembling and pull-out force of the suspension bearings during operation, and also ensures the performance of the bearing parts under low temperature. The outer cover and base are connected by a “flip-fastener” structure, which ensures the assemblability of the suspension bearings and the pull-off force during operation. Moreover, a metal support ring is designed outside the base of the suspension bearings, which effectively reduces the deformation of the bearing when it bears the single-point centralised force of the helical spring, ensures the rotational accuracy of the suspension bearings, and satisfies steering requirements;

The project of “R&D and Application of High Temperature Tapered Roller Bearings” researched the influence of friction torque and dynamic load on the performance and life of high temperature tapered roller bearings, and carried out optimisation of the structure and parameters, which prolonged the service life of the bearings;

The project of “Development and Application of Split Bearing Unit for Marine Traffic Equipment” invented an adjustable cylindrical roller split bearing unit and an axial floating structure, and the bearing seat of the cylindrical roller bearings is internal spherical, and the bearing box is external spherical, which can realise the function of adjusting the centre of gravity at a certain angle in any direction, and solved the problems of flexural, alignment and machining errors of the long straight axle. It solves the problems of flexure, alignment and processing error of long straight shafts, and facilitates disassembly and assembly.

The nine project bearings of Waxaxial Group have been installed and applied by many customers, which have shown that they run reliably and with good effects, meeting the requirements for use and bringing significant economic and social benefits.