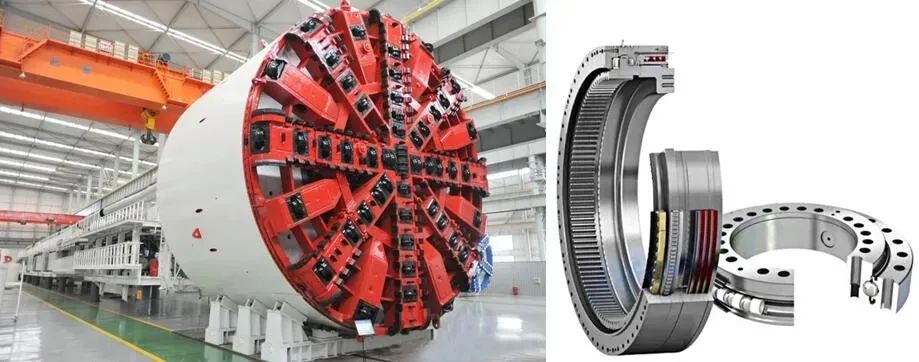

Recently, in Changsha, Hunan Province, China Railway Construction Heavy Industry Group Corporation (hereinafter referred to as the second industrial park, a code-named “197” plant, the diameter of 3 metres to 8.6 metres of a number of “large iron ring” is being processed and manufactured.

These “big iron rings” are called main bearings, which are the “heart” of the shield machine.

It is the only component that cannot be replaced during the service period of the shield machine, and it needs to face the test of extremely harsh working conditions such as super-heavy load, large partial load, and frequent variable load of the shield machine.

Once the main bearing is damaged after moulding, the shield machine with hundreds of millions of dollars will face the danger of being scrapped, and the cost of the whole project will also increase exponentially.

The manufacture of shield machine main bearings used to be a difficult problem restricting China’s industrial development.

“To achieve high-level scientific and technological self-reliance, it is necessary to carry out more innovative research and breakthroughs in key technical problems.” Liu Feixiang, a deputy to the National People’s Congress and chief scientist of Tiejian Heavy Industry, said that China’s shield machine industry should not only achieve global leadership in machine technology and the largest market share in the world, but also realise independent control of key systems.

In recent years, Tiejian Heavy Industry, relying on the advantages of the new national system, to strengthen the government, industry, academia, research and use of collaborative innovation, for heavy-duty large bearings, control systems, reducers, hydraulic pumps and motors, such as key components of the shield machine to carry out independent research and development, and to achieve the key components of the completely independent and controllable.

“The service life and reliability of the main bearing is constrained by a variety of key factors such as materials, design, manufacturing technology, etc., and the difficulty of development multiplies with the increase in size.” Speaking of the weak link in China’s shield machine industry, Liu Feixiang feel very deeply, “In the past, foreign enterprises not only in the technology card us, but also year by year to increase the price increase.”

Main bearing development in the end how difficult?

Liu Feixiang summed up four major difficulties: difficult materials, difficult design, difficult manufacturing, difficult testing.

Large diameter main bearing, for example, its raceway diameter of several metres, flatness should be less than 20 microns, equivalent to one-fifth of the thickness of a piece of A4 paper, straightness should be less than 8 microns, only one-tenth of a hair.

Such a manufacturing process is the same as “carving words on the hair, carving flowers on the grain of rice”.

In July 2019, Liu Feixiang led the establishment of the R & D team, joint upstream and downstream enterprises, colleges and universities to collaborate on research, try hundreds of materials and processes, and field tests, tens of thousands of sets of data analysis. 2023 October, the team successfully developed the main bearing of the shield machine with a diameter of 8.61 m. This marks the first time that our country has completely overcome the problem of the shield machine bearing, and the first time that the shield machine bearing has been successfully developed. This marks that China has completely overcome and independently mastered the shield machine main bearing from the material, design to manufacturing, test the whole process of key core technologies, so that the domestic shield machine has a full range of “Chinese heart”.

At the same time in the continuous attack on the core technology, Tiejian Heavy Industry to accelerate the digital transformation, through the digital empowerment, innovation to create a set of shield machine digital twin system, so that the great power of the heavy weapon burst “digital intelligence” power.

“This system through real-time collection of engineering and construction data, such as shield machine various parts of the operating data, underground environmental data, and then after system analysis, remote online real-time to help technicians for the current model to make operational decisions, and optimisation and upgrading of the next generation of products to provide big data support.” Liu Feixiang said that the digital twin technology breaks the boundary between reality and reality, avoiding the errors that occurred in the past on-site manual survey, and realising the risk of moving forward.

Today, the underground engineering equipment digital twin system of Tiejian Heavy Industry has been extended to the shield machine, drilling and blasting method equipment and coal mining equipment, widely used in domestic and foreign railways, highways, mines, water conservancy and other large-scale engineering construction.

From the breakthrough to global leadership, how to make the domestic high-end manufacturing industry, including China’s shield machine industry continue to lead? Liu Feixiang believes that to strengthen the high-end manufacturing industry as the cornerstone of high-quality development, through the attack on key technologies, so that the industrial short board is not short, the attack on intelligent technology, so that the industrial long board longer, with high-quality industry to lift the high-quality development of the economy.