According to the introduction, the main bearing diameter 8.01 meters, weighing 60 tons, is China's first set of the largest diameter, the single heaviest shield machine with the main bearing, can be applied to the diameter of 16 meters class super-large shield machine.

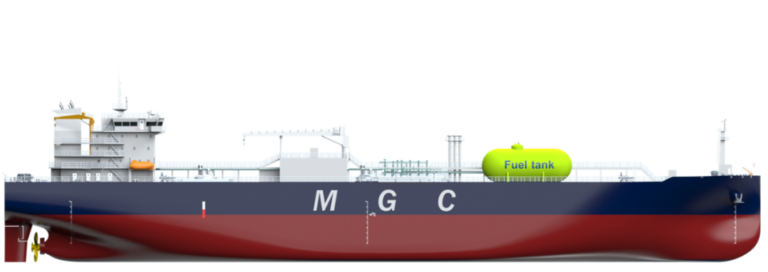

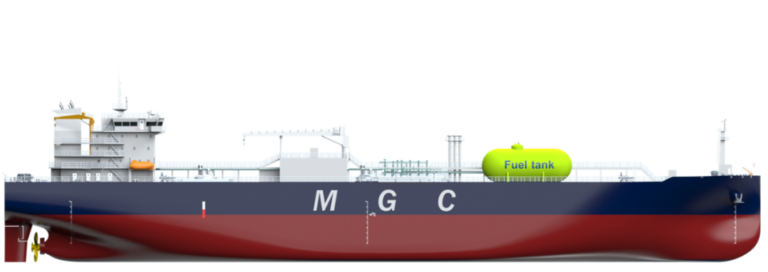

Gao Wenbao, Vice President of CIMC Anrico and General Manager of CIMC Pacific Offshore, said that CIMC Pacific Offshore has continued to deepen its efforts to build a full range of medium-sized LPG carriers, with current products covering various LPG, ethane, ethylene, LNG, liquid ammonia and other LPG carriers. In the future, it will continue to enrich its products and services and continue to provide customers with energy-saving, environmentally friendly and technically innovative integrated LPG transportation solutions.

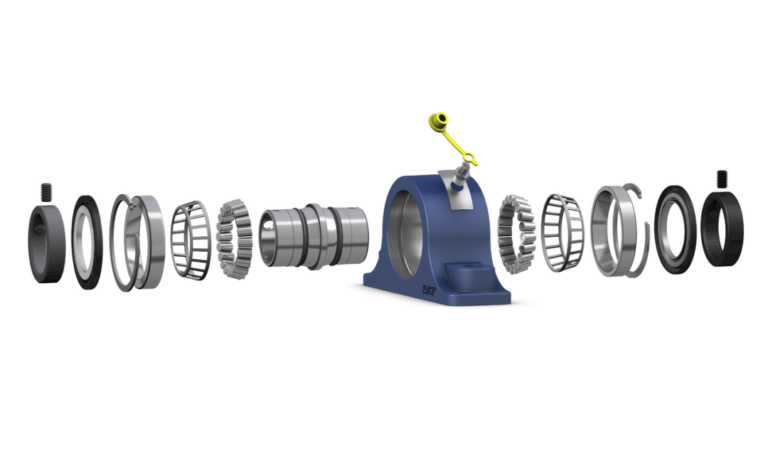

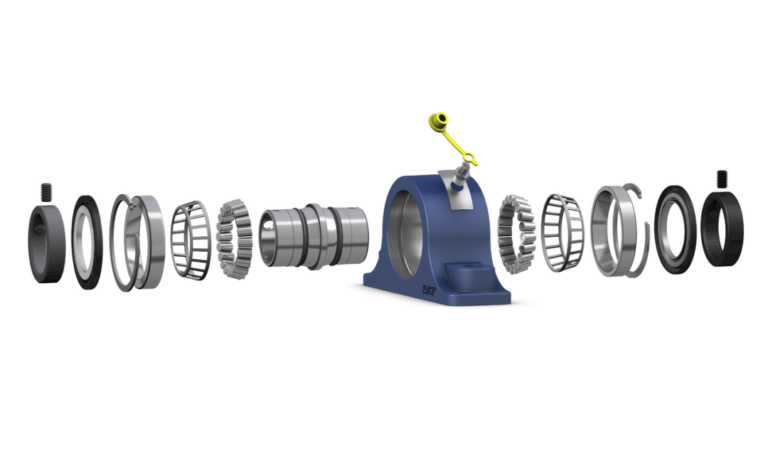

We are proud that our extensive knowledge and experience in the field of bearings has been able to initiate the product range rules for the bearing industry, which is an important milestone for SKF and the industry as a whole.

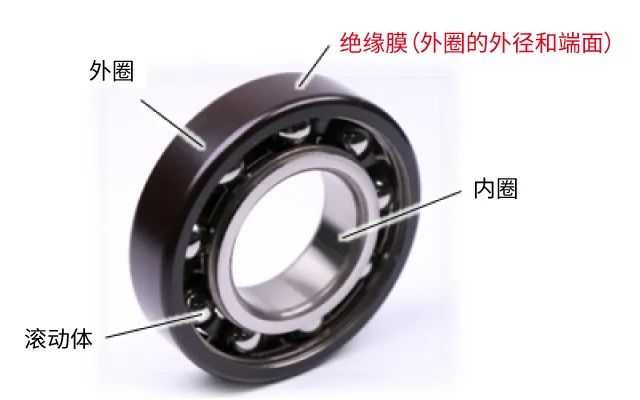

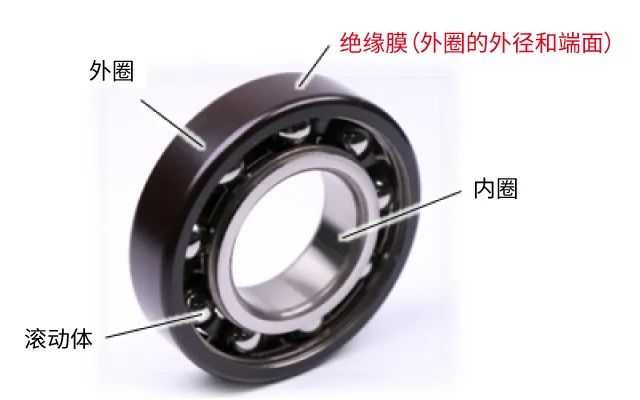

In the process of installation, we should also pay attention to the problems that may lead to such as gasket deformation, front cover crimping to produce margin, clearance is too large or too small, etc., to ensure that the installed bearings can maintain the best operating condition, long time operation without failure.

The theme of the competition is "New Journey, High Quality, Create the Future", and the competition will be an important activity of the National Quality Month 2023 and the World Manufacturing Conference 2023, which will be important for the sustainable development of China's machinery industry and improve its international competitiveness. It will be of great significance to the sustainable development of the Chinese machinery industry and the improvement of its international competitiveness.

This month, the Jinan Phase II project was completed and put into operation following SKF's Changshan Phase II project, while the Xinchang Phase III project and Dalian Phase IV project are also under steady construction, which are expected to further enhance SKF's comprehensive capabilities in China, better position itself in China and provide quality products and services to customers worldwide.

To prevent the passage of electric current inside the bearing, NTN has coated the outer diameter and end surfaces of the bearing with an insulating film that can withstand voltages of 100V or more, providing excellent insulating characteristics and responding to the market trend towards higher voltages in new energy vehicles.

In the long run, the high energy consumption of traditional fans and pumps, which account for a large proportion of the overall energy consumption, and the long working runs, with expensive electricity costs, especially in the middle and later stages of maintenance and losses are particularly noticeable, leading to increased energy consumption as well as expenditure for the whole system. The use of magnetic floating bearings also saves on the configuration costs of some devices, such as lubrication systems, gear drives, cooling systems, etc. When converted into the cost of magnetic floating bearings, the amount is considerable.

The Tibet Zabuye source-grid-load-storage integrated energy supply project is an early and pilot "Everest" project invested and constructed by Baowu Clean Energy Co. The project is a pilot project to provide a safe, stable and reliable integrated energy supply around the clock.

NSK China Headquarters and China R&D Centre Phase II held a groundbreaking ceremony in the Huaqiao Economic Development Zone in Kunshan City. The project is expected to be completed in August 2024.