The project introduces domestic and foreign high-efficiency, energy-saving, environmentally friendly automated production equipment, including the world's largest and most advanced fully automated circular sawing and forging pick-up dual-use manipulator, can be achieved in the production process of "near-final" rolling ring mill, and multi-functional, high-precision forging presses.

In the promising new energy era, HEMS will take Chengdu base as the landing point, radiate a wider map with stronger production and delivery capacity, explore a wider market, and compete for the international leading position in lithium-ion battery, photovoltaic and other circuits.

Through the smooth implementation of the project, it can provide innovative demonstration for large users to develop, open up "new energy +", large base construction and thermal power transformation implementation path, explore high-power and long-time energy storage solutions, promote the coupling technology of compressed air + lithium battery energy storage to complete the product stereotypes and standardisation, form commercial promotion and application, and promote the high quality development of the new energy storage industry of the State Power Investment Corporation.

This project reflects the strong market adaptability of Shanghai Electric's all-vanadium current battery energy storage products, which can meet the needs of customers' "private customisation".

Low start-up torque and low friction give the gearbox a new lease of life!

At the ceremony, with the unveiling of the red curtain, the huge XCMG concrete equipment was gradually revealed, and the metallic luster was eye-catching under the light, and dozens of equipments were about to go to the market area of "One Belt, One Road".

SKF has always had a close partnership with CSR for many years. This time, SKF won the 2023 "Hand in Hand Award", which is not only a recognition of the past year, but also reflects that both sides in the enterprise strategy and vision, jointly planning new energy automobile development planning and action paths, to build a community of destiny for the development of the industry, and work hand in hand to go to a new chapter.

The signing of the three bearing manufacturing projects with a total investment of 870 million yuan, including the Weiyuan rolling body intelligent automated production base construction project, Karel bearing production and processing projects and Jinguanda large-scale precision ring parts processing project.

SINOMACH Group has leveraged its resource advantages to continue to plough into the international market and promote the high-quality development of the "Belt and Road". Recently Successfully won a number of overseas projects

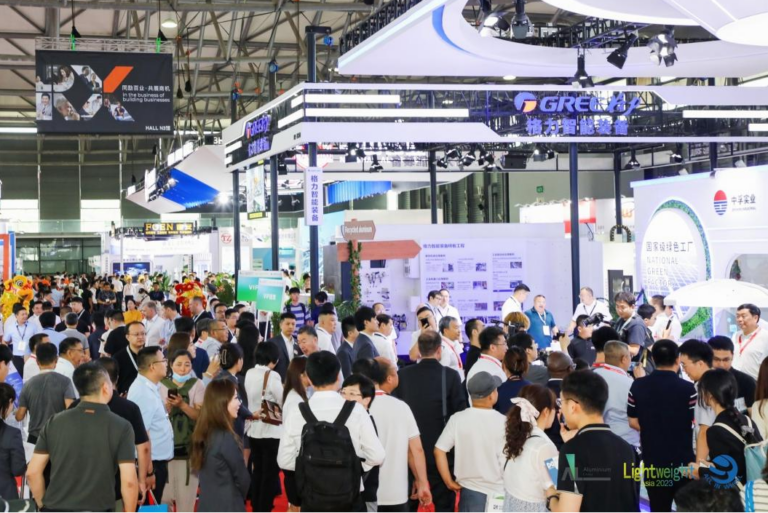

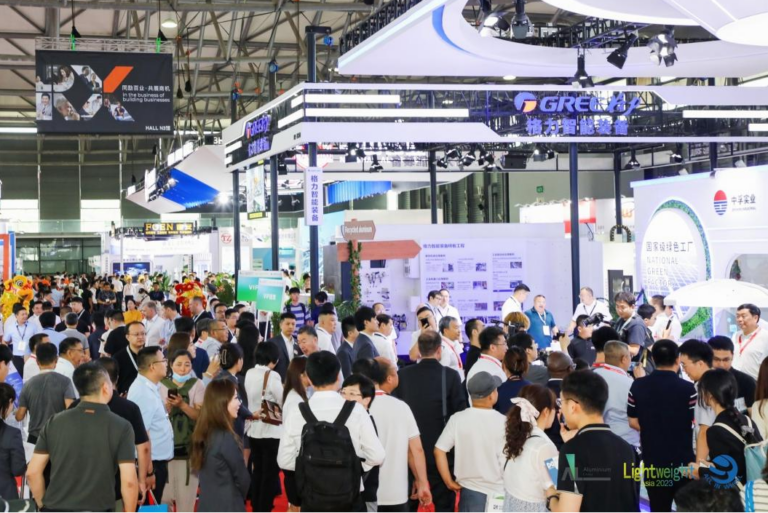

In the future, Gree will continue to plough into the field of intelligent equipment, meet new challenges in the aluminium processing industry, continue to develop and innovate, and actively promote the transformation of the aluminium processing industry to modernization under the wave of digital transformation, and promote the benign interaction and coordinated development of technology and application.